Have you drawn the mechanical equipment drawing by yourself?

Mechanical engineers normally think about mechanical equipment design and we leave the CAD operator to make drawings.

That’s because the most important thing is to find out the best combination of mechanical equipment from the point of saving energy, etc…

Most companies hire CAD operators or have a contract with other architecture companies.

Mechanical engineers lose a chance to make drawings.

Which means they can not read them in detail.

Especially younger mechanical engineers are like that.

They sometimes don’t understand why something is written in the drawing.

This article is for the younger engineers on how to make duct drawings.

(This time for brunch duct.)

There are 3 types of dust drawing normally.

The one is the duct for air conditioning which provides cool or warm air from the air conditioner.

The second is the duct for ventilation which provides fresh air or remove air with a fan.

The last is the duct for the smoke exhaust which removes the smoke air in the case of an emergency.

We sometimes make one drawing with 3 types of duct systems.

(It depends on how easy to read its drawings.)

Before making drawing

We should decide the amount of air in a room at first.

The next step is to decide the quantity of diffuser and position.

Howe to draw the duct drawing

Then we can start drawing.

How to draw the duct equipment, especially the branch duct.

First, we need to check what kind of duct we are drawing.

OA, SA, RA, or EA.

It’s different from the type of ducts how to draw symbols.

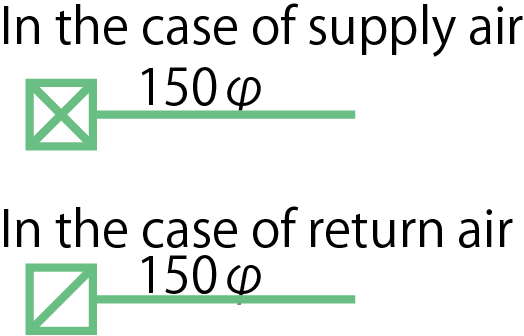

In the case of OA or SA, we write the symbol for diffusers with a square and cross mark.

In the case of RA or EA, we use it with a square and diagonal line.

It’s the standard symbol and everyone who is working as a mechanical engineer can read them easily.

You can change them if you put the usage guide.

Next is how to calculate the size of the duct.

You can find the chart on the internet with keywords such as the size of the duct, chart, and pressure loss.

And also you can find the free software about it on the internet.

The basic way of calculating the size of the duct is that we decide that it is less than 1Pa/m a pressure loss per 1m.

It’s gonna be also OK if we decide it over 1pa/m.

The problem of not following its guideline is making noise, so we need to choose a bigger fan, even if the duct size is almost the same.

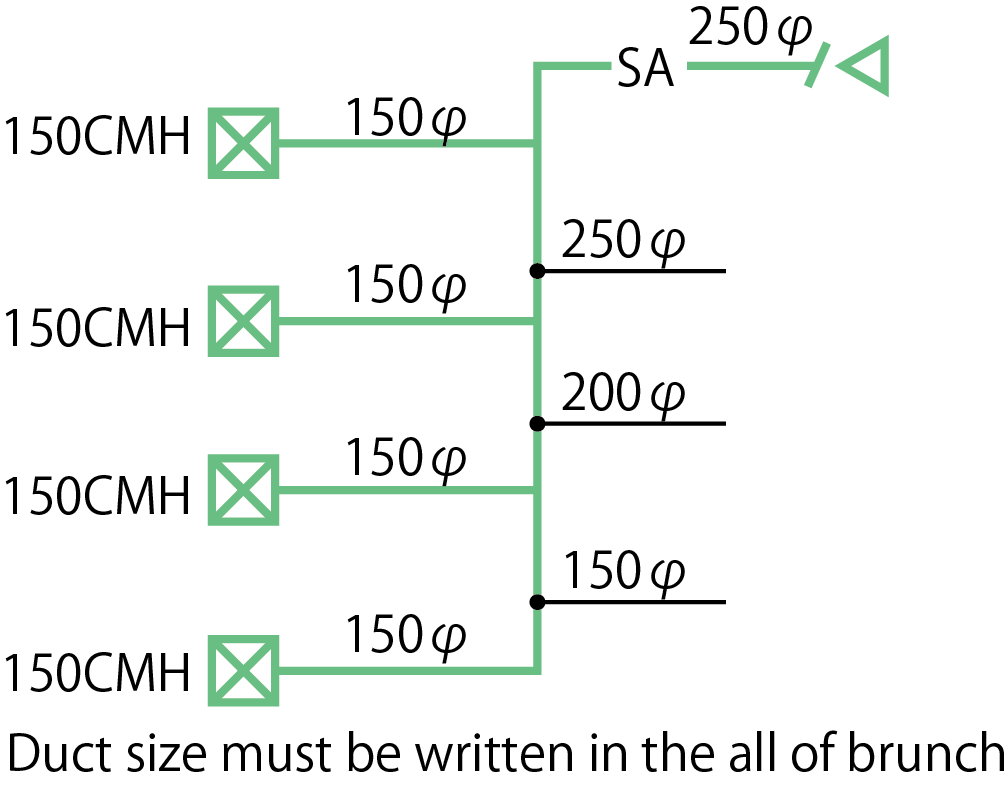

The duct size will be put on the duct.

When there are many brunch ducts, you should care of them.

Sometimes we can find the drawing with an unknown duct size.

That’s because when there are many branches, we sometimes forget to put the duct size on the drawing.

One of the important things is to put the duct size in all sections of the duct.

I just introduce how to draw the brunch duct this time.

No fans, air intake, no vent cap, and outdoor grilles.

Grille size and box size

Next is about grilles and the box for the grille.

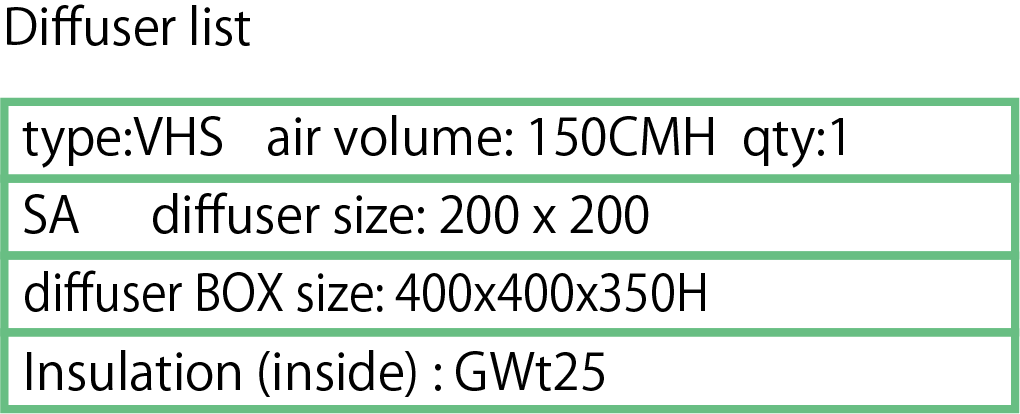

When we make the duct drawings, we should draw the diffuser lists and box lists.

I will introduce how to calculate the size of the grille.

Wind speed on the surface of the grille is 2.0m/s normally to avoid noise except for nozzle type of diffusers.

And the efficient area is 70% of the diffuser size.

VHS is used for the supply air and HS is used for the return air.

BOX size (horizontal) is diffuser size +200mm.

Also, we need to calculate the BOX size from the duct size. (BOX inlet)

BOX size (vertical) is duct size +200mm.

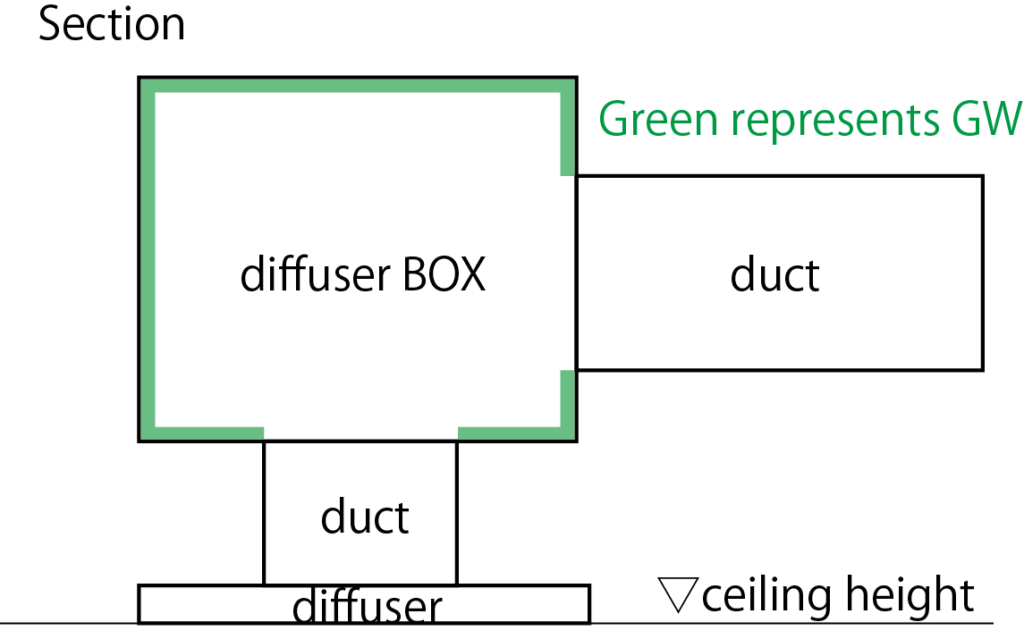

Insulation in the diffuser BOX

The reason that insulation is installed is noise.

Supply air comes from a fan or an air handling unit with noise.

Insulation suppresses the noise and the insulation should be installed inside of the BOX.

Insulation should be indicated in the drawing.

Summary

I introduced how to draw the brunch duct in the duct drawing.

We do not understand why it is like that as long as we don’t care about it.

コメント